Energy Savings Strategies for Professional Organizations: Maximizing Efficiency and Reducing Costs

- TheFitProfessional1

- Jun 27, 2024

- 11 min read

Updated: Mar 20

By Paul T Ayres

Annual savings in costs in millions of dollars is not just for manufacturing organizations anymore. In today's rapidly evolving business environment, professional organizations are increasingly recognizing the importance of energy efficiency. Implementing energy-saving measures not only helps reduce operational costs but also contributes to environmental sustainability. This article will either remind us of or introduce effective strategies for reducing energy consumption in our organizations, regardless of their type.

Potential cost savings are substantial and the examples I have included are backed by credible sources. Many of these also fit services businesses and will be a bit of an epiphany for some. These ideas are no longer just for manufacturing environments. It is so common for companies in service businesses like law, accounting, finance, healthcare, or hospitality to overlook this opportunity. Don’t be one of those!

We will take you through just FOUR of the many approaches to ENERGY SAVINGS.

In this order, you will find useful information on the following:

1. Investing in Energy-Efficient Office Equipment.

2. Implementation of Energy Management Systems in Organizations.

3. Implementation of Renewable Energy Systems in Organizations.

4. Can Data Collection Sensors Work for You? How Sensors Save Energy Costs in Construction, Distribution, Manufacturing, and Service Based Systems.

📢 Read on. This is better than finding a fifty-dollar bill between the couch cushions!

1. Investing in Energy-Efficient Office Equipment

Yeah, yeah! We know, but how many of the readers actually take these simple steps? Read on, because it could be an email communication that is going to put $17,000 dollars right to your bottom line every year (depending on your organization's size). We covered some of these in one Margin Max Minute episode covering ten cost reduction strategies too. Here, I have included some additional savings estimates. These can be substantial for any size and anytime of organization and of course, the recommendation is not to overlook these. Here is your friendly reminder!

Energy-Efficient Computers and Monitors:

Upgrading to ENERGY STAR-certified computers and monitors can lead to substantial energy savings. ENERGY STAR estimates that certified computers use up to 30% less energy than conventional models (ENERGY STAR, "Computers," 2022). For an office with 100 computers, this could translate to savings of approximately $1,200 annually, assuming an average electricity cost of $0.13 per kWh.

Laptops Instead of Desktops:

This was definitely a learning point for me. It makes intuitive sense for sure. Laptops typically consume less power than desktop computers. The Natural Resources Defense Council (NRDC) highlights that laptops can be significantly more energy-efficient (Pierre Delforge, NRDC, "How Energy-Efficient Is Your Computer?" 2020). Replacing 100 desktops with laptops could save an organization around $3,000 per year, considering an average desktop uses 200 kWh annually compared to 50 kWh for a laptop.

LED Lighting:

I think this one is likely a reminder for you. Also, there is a ‘feel’ component to this approach. The light is definitely different (or can be depending on where you are now). Switching to LED lighting is another effective measure. LEDs use up to 75% less energy than traditional incandescent bulbs and last up to 25 times longer (U.S. Department of Energy, "LED Lighting," 2022). For an office with 1,000 light fixtures, converting to LEDs could save around $10,000 annually, given typical energy savings and bulb longevity.

Smart Power Strips:

Of course, as I stated in the Margin Max Minute version of this article, we can simply turn the lights off. But, we are human, and what do humans do? We forget or get distracted. So why not eliminate the need to remember every time we leave the room? So many offices do not utilize this approach. Or do so only in the bathroom and conference rooms. It's time to consider this approach everywhere it is practical. Smart power strips help eliminate "phantom" energy use by automatically cutting off power to devices not in use. The U.S. Department of Energy estimates that smart power strips can save an average household about $100 per year (U.S. Department of Energy, "Smart Power Strips," 2022). In a large office setting, the savings could be much higher, potentially around $2,000 annually for 20 smart power strips.

Energy-Efficient Printers:

Choosing ENERGY STAR-certified printers with duplex printing capabilities reduces energy consumption and paper use. ENERGY STAR notes that certified printers are designed to be more energy-efficient (ENERGY STAR, "Printers," 2022). For an office with 50 printers, this could mean savings of about $1,000 per year.

Potential Cost Savings

To illustrate potential savings, let's consider a hypothetical professional organization with 100 employees:

· Energy-Efficient Computers and Monitors: $1,200 annual savings

· Laptops Instead of Desktops: $3,000 annual savings

· LED Lighting: $10,000 annual savings

· Smart Power Strips: $2,000 annual savings

· Energy-Efficient Printers: $1,000 annual savings

In total, these measures could save the organization approximately $17,200 annually. Not bad, $170.00 per employee per year!

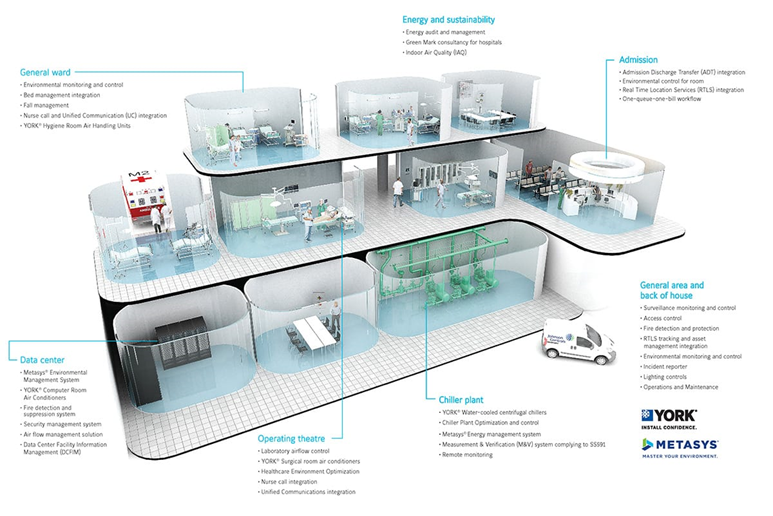

2. Implementation of Energy Management Systems in Manufacturing: Definition, Functionality, and Cost Savings

What is an Energy Management System (EMS)?

An Energy Management System (EMS) is a comprehensive solution designed to monitor, control, and optimize energy usage in various settings, including manufacturing facilities. It integrates hardware, software, and data analytics to provide real-time insights and automation capabilities that enhance energy efficiency and reduce operational costs. An EMS typically includes components such as data collection sensors, metering devices, control systems, and a centralized platform for data analysis and reporting.

How an EMS Works?

An EMS functions by continuously collecting data on energy consumption from various sources within a facility. This data is then analyzed to identify patterns, inefficiencies, and opportunities for optimization. The system can automatically adjust energy usage based on real-time needs, such as dimming lights, adjusting HVAC settings, or shutting down idle machinery. Additionally, an EMS provides detailed reports and dashboards that help facility managers make informed decisions to further enhance energy efficiency.

Implementation Example: Johnson Controls at a Manufacturing Facility

Company: Johnson Controls

Johnson Controls implemented an Energy Management System at a large manufacturing facility to improve energy efficiency and reduce costs.

The EMS included the following key components:

1. Data Collection Sensors: Installed throughout the facility to monitor energy usage in real time.

2. Automated Controls: Integrated with lighting, HVAC, and machinery systems to adjust energy consumption based on current requirements.

3. Centralized Platform: Provided a comprehensive view of energy data, allowing for detailed analysis and reporting.

Functionality:

1. Real-Time Monitoring: Sensors continuously tracked energy consumption across different areas of the facility.

2. Data Analysis: The EMS analyzed the data to identify inefficiencies, such as excessive energy use during non-peak hours or under-utilized equipment.

3. Automated Adjustments: Based on the analysis, the system automatically adjusted settings to optimize energy use, such as reducing HVAC operation during low-occupancy periods and turning off lights in unoccupied areas.

4. Reporting and Insights: Facility managers received regular reports and insights on energy consumption patterns and savings opportunities, enabling them to implement further improvements.

Savings:

According to Johnson Controls, the implementation of the EMS resulted in a 25% reduction in energy consumption at the manufacturing facility. This translated to annual savings of approximately $1.8 million, considering the facility's initial energy expenditure.

Source: Johnson Controls, "Energy Management Solutions for Manufacturing Efficiency," 2021.

3. Implementation of Renewable Energy Systems in Manufacturing: Definition, Functionality, and Cost Savings

What are Renewable Energy Systems?

Renewable energy systems are technologies that generate energy from natural sources that are continuously replenished, such as sunlight, wind, water, and geothermal heat. These systems include solar panels, wind turbines, hydroelectric generators, and geothermal plants. Renewable energy systems are designed to provide a sustainable and environmentally friendly alternative to traditional fossil fuel-based energy sources, reducing greenhouse gas emissions and dependency on non-renewable resources.

How Renewable Energy Systems Work?

Renewable energy systems harness natural resources to generate electricity or thermal energy. The generated energy can be used on-site to power operations or can be fed back into the grid.

Key components of renewable energy systems include:

1. Solar Panels (Photovoltaic Systems): Convert sunlight directly into electricity using semiconductor materials.

2. Wind Turbines: Capture wind energy and convert it into mechanical power, which is then converted into electricity.

3. Hydroelectric Generators: Utilize flowing water to spin turbines connected to generators, producing electricity.

4. Geothermal Plants: Extract heat from the Earth to generate electricity or provide direct heating.

Implementation Example: Solar Panels at Tesla’s Gigafactory

Company: Tesla

Tesla implemented a large-scale solar panel system at its Gigafactory in Nevada. The system is designed to provide a significant portion of the facility's energy needs through renewable sources, reducing reliance on the grid and lowering overall energy costs.

Functionality:

1. Solar Panel Installation: Thousands of solar panels were installed on the roof of the Gigafactory and on surrounding land.

2. Energy Storage: The system is integrated with Tesla’s energy storage solutions (Powerpacks), which store excess energy generated during the day for use during peak demand times or when solar generation is low.

3. Grid Integration: The system can feed excess energy back into the local grid, providing additional revenue through energy credits and supporting the grid with renewable power.

Savings:

Tesla estimates that the solar panel system at the Gigafactory reduces its annual energy costs by approximately $5 million. The system generates around 70 MW of power, significantly offsetting the factory's energy consumption.

Source: Elon Musk, Tesla, "Sustainable Energy Solutions at Tesla’s Gigafactory," 2022.

Benefits and Cost Savings of Renewable Energy Systems

Implementing renewable energy systems in manufacturing settings offers numerous benefits, including:

· Reduced Energy Costs: Renewable energy systems can significantly lower electricity bills by generating on-site power, reducing the need for grid electricity.

· Energy Independence: By producing their own energy, manufacturers become less dependent on external energy providers and more resilient to energy price fluctuations.

· Environmental Impact: Renewable energy systems reduce greenhouse gas emissions and contribute to sustainability goals, enhancing the company’s environmental credentials.

4. CAN DATA COLLECTION SENSORS WORK FOR YOU? How Sensors Save Energy Costs in Construction, Distribution, Manufacturing, and Service-Based Systems

We now live in a world with huge computing power and data storage capabilities. Not many years ago such opportunities were reserved for huge corporations, governments, and universities. Now, with the power of data at our fingertips we can combine the power of Artificial Intelligence and Machine Learning to maximize opportunities.

Data collection systems used to reduce energy consumption are integrated technologies that monitor, analyze, and manage energy usage within a facility. These systems include a network of sensors, meters, and data loggers that continuously collect real-time data on various parameters such as electricity, gas, water usage, and equipment performance. The data is then transmitted to a centralized platform for analysis, where advanced algorithms identify patterns, inefficiencies, and opportunities for optimization.

By providing detailed insights and enabling automated controls, data collection systems help facilities optimize energy usage, reduce waste, and achieve significant cost savings. Utilizing data collection sensors is the first step in your automation plan, well before we get to AI or ML.

Here are some great examples I believe will spur some great thinking for you to assess opportunities in your organization:

1. Real-Time Monitoring and Optimization

Example: Siemens Plant in Amberg, Germany

Siemens implemented an extensive network of data collection sensors at their electronics manufacturing plant in Amberg, Germany. These sensors monitor various parameters such as machine performance, temperature, and energy consumption. By analyzing the real-time data, Siemens optimized their production processes, reducing energy waste and improving overall efficiency.

Savings:

According to Siemens, the implementation of data collection sensors has led to a 15% reduction in energy consumption at the Amberg plant. This reduction translates to annual savings of approximately $1.4 million (Siemens, "Energy Efficiency in Manufacturing," 2020).

2. Predictive Maintenance

Example: General Electric (GE) Aviation

General Electric (GE) Aviation uses data collection sensors to monitor the condition of their manufacturing equipment. These sensors predict when a machine is likely to fail or require maintenance, allowing GE to perform maintenance only when necessary rather than on a fixed schedule. This predictive maintenance approach reduces energy waste from malfunctioning equipment and minimizes downtime.

Savings:

GE reported that predictive maintenance using data collection sensors has resulted in a 10% reduction in energy costs at their aviation manufacturing facilities. This equates to annual savings of around $2.2 million (John Flannery, GE Aviation, "Smart Manufacturing with Predictive Maintenance," 2019).

3. Energy Management Systems

Example: Schneider Electric

Schneider Electric incorporated data collection sensors into their energy management system (EMS) across multiple manufacturing sites. These sensors collect data on energy usage patterns, enabling Schneider to identify inefficiencies and implement corrective measures. The EMS uses the data to automate energy-saving actions, such as adjusting lighting and HVAC systems based on real-time needs.

Savings:

By integrating data collection sensors into their EMS, Schneider Electric achieved a 20% reduction in energy consumption across their facilities. This reduction amounts to annual savings of approximately $3 million (Jean-Pascal Tricoire, Schneider Electric, "Energy Management Systems for Smart Manufacturing," 2021).

Conclusion

Professional organizations have much to gain from adopting energy-efficient practices and technologies. Not only do these measures reduce operational costs, but they also promote sustainability and corporate responsibility. By investing in efficient equipment, and leveraging smart technologies, businesses can achieve significant energy savings and contribute positively to the environment. By implementing these strategies, professional organizations can not only reduce their energy consumption but also realize significant cost savings, making energy efficiency a smart and sustainable business decision.

Also, the adoption of data collection sensors in manufacturing settings offers significant potential for energy cost savings. Real-time monitoring, predictive maintenance, and comprehensive energy management systems are just a few ways these sensors can optimize energy use. The examples of Siemens, GE Aviation, and Schneider Electric demonstrate that investing in data collection sensors can lead to millions of dollars in annual savings, making them a valuable asset for manufacturers seeking to enhance efficiency and reduce costs. By leveraging the power of data collection sensors, manufacturers can not only cut energy costs but also improve operational efficiency and sustainability, positioning themselves for long-term success in a competitive market.

Don’t forget to consider EMS! Implementation of an Energy Management System in a manufacturing setting offers substantial benefits, including significant cost savings, improved operational efficiency, and enhanced sustainability. By leveraging real-time data collection, advanced analytics, and automated controls, an EMS enables manufacturers to optimize energy use and reduce waste. The example of Johnson Controls demonstrates the tangible financial impact and operational improvements that an EMS can deliver.

If you can accept some unreliability in a constant energy flow, renewables might be for you. The application of expensive storage solutions can overcome unreliability in part. It comes down to the numbers. The adoption of renewable energy systems in manufacturing facilities provides substantial financial and environmental benefits. By investing in technologies such as solar panels, wind turbines, and energy storage systems, manufacturers can achieve significant cost savings, enhance energy independence, and contribute to a more sustainable future. The example of Tesla’s Gigafactory demonstrates the potential of renewable energy systems to transform energy usage in manufacturing, delivering millions of dollars in annual savings.

What are you waiting for?! Get your team to assess the potential energy savings. If your company has looked at this in the last few years, I recommend dusting the analysis off again. We can miss opportunities, and changes can drive inefficiencies too. Give energy savings a look, you won’t be sorry.

References

U.S. Department of Energy. "Energy Audits." 2022. Energy Audits

ENERGY STAR. "Computers." 2022. Computers

Delforge, Pierre. Natural Resources Defense Council (NRDC). "How Energy-Efficient Is Your Computer?" 2020. NRDC

U.S. Department of Energy. "LED Lighting." 2022. LED Lighting

U.S. Department of Energy. "Smart Power Strips." 2022. Smart Power Strips

ENERGY STAR. "Printers." 2022. Printers

U.S. Department of Energy. "Energy Management Systems." 2022. Energy Management Systems

World Business Council for Sustainable Development (WBCSD). "Renewable Energy in the Corporate Sector." 2021. WBCSD

Siemens. "Energy Efficiency in Manufacturing." 2020.

Flannery, John. General Electric Aviation. "Smart Manufacturing with Predictive Maintenance." 2019.

Tricoire, Jean-Pascal. Schneider Electric. "Energy Management Systems for Smart Manufacturing." 2021.

References

Johnson Controls. "Energy Management Solutions for Manufacturing Efficiency." 2021.

Siemens. "Energy Efficiency in Manufacturing." 2020.

Flannery, John. General Electric Aviation. "Smart Manufacturing with Predictive Maintenance." 2019.

Tricoire, Jean-Pascal. Schneider Electric. "Energy Management Systems for Smart Manufacturing." 2021.

Musk, Elon. Tesla. "Sustainable Energy Solutions at Tesla’s Gigafactory." 2022.

Johnson Controls. "Energy Management Solutions for Manufacturing Efficiency." 2021.

Siemens. "Energy Efficiency in Manufacturing." 2020.

Flannery, John. General Electric Aviation. "Smart Manufacturing with Predictive Maintenance." 2019.

Tricoire, Jean-Pascal. Schneider Electric. "Energy Management Systems for Smart Manufacturing." 2021.

TheFitProfessional1, LLC, 2024.

Comments